MASTERINJECT MJ-01 AUTO-START

SEMI-AUTOMATIC WAX INJECTORS

Features Model MJ-01-C13A SMART

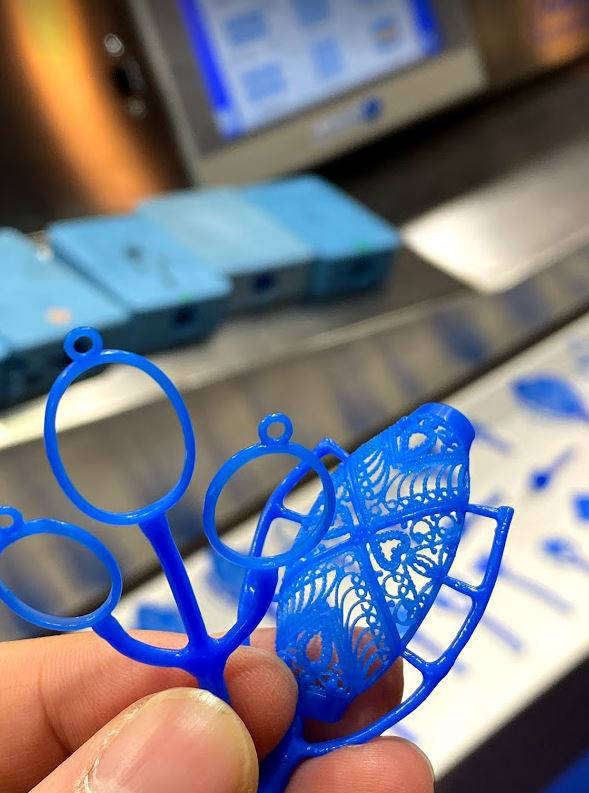

Semi-Automatic wax injector, single workstation in right position for individual operator, equipped with aluminum tank (capacity of 4.5 Kg), injection system by piston of 25 cm³, exterior and removable touch screen of 7”, RFID reader and writer, with self-centering clamp C13A (Size 130x120 x50 mm) and pump included VAP14.

Dimensions: (WxDxH)

Machine: 55x32x45 cm

Packing: 65x55x65 cm

Weight

Machine: 30kg

Packing: 54kg

Power supply: 240VAC / 120VAC (optional)

System pressure: 6 bar

SEMI-AUTOMATIC WAX INJECTORS

MASTERINJECT MJ-02 AUTO-START

SEMI-AUTOMATIC WAX INJECTORS

Features Model MJ-02-C13AC13A SMART

Semi-Automatic wax injector, double workstation for individual or double operator, equipped with aluminum tank (capacity of 4.5 Kg), two injection system by piston of 25 cm³, two external and removable touch screen of 7”, two RFID reader and writer, two self-centering clamp C13A (Size 130x120 x50 mm) and pump included VAP14.

Dimensions: (WxDxH)

Machine: 92x34x48 cm

Packing: 95x55x65 cm

Weight:

Machine: 46 Kg

Packing: 75 Kg

Power supply:

System pressure: 6 Bar

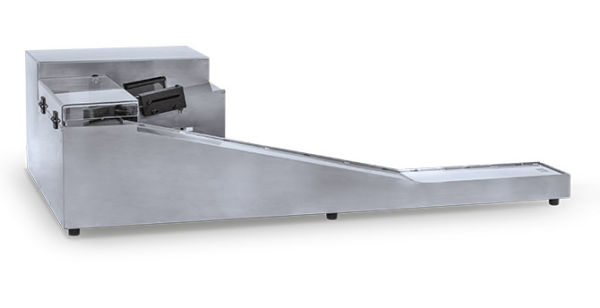

MASTERINJECT MI-03

FULLY AUTOMATIC WAX INJECTORS

Features MI-03 SMART

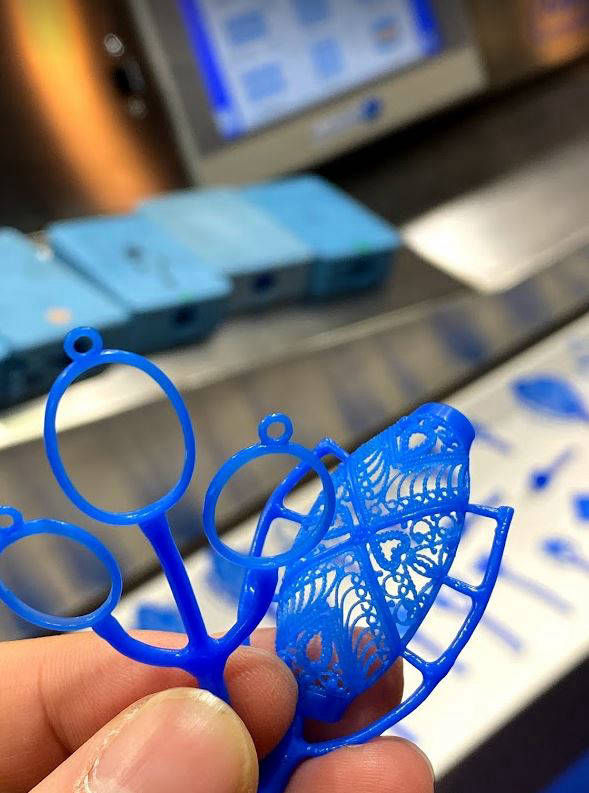

Fully automatic wax injector for single or dual operator, equipped with aluminum tank (capacity 4,5 Kg), injection system by piston of 10 cm³, touch screen of 7”, RFID reader and writer, self-centering clamp (Size Plate 100x100x50 mm), automatic loader and unloader moulds (Size 100x100 mm), cooling system for moulds and pump included VAP14.

International Patent Pending

The feature that makes the only MI-03 in the market, is to work on a continuous cycle through a charger of vertical molds, loading and fully automatic unloading and cooler for the molds, integrated in the machine. It is the first and only automatic injector to be covered by international patent pending

Dimensions: (WxDxH)

Machine: 96x65x45 cm

Packing: 115x80x65 cm

Weight:

Machine: 44kg

Packing: 83kg

Power supply: 240VAC / 120VAC (optional)

System pressure: 6 bar

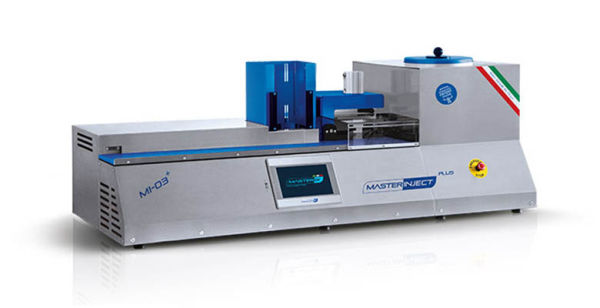

MASTERINJECT MI-03 PLUS

FULLY AUTOMATIC

Features MI-03 plus

Fully automatic wax injector for single or dual operator, equipped with aluminum tank (capacity 4,5 Kg), injection system by piston of 25 cm³, touch screen of 7”, RFID reader and writer, self-centering clamp (Size Plate 150x130x55 mm), automatic loader and unloader moulds ( Size 150x130 mm ), cooling system for moulds and pump included VAP18.

Dimensions (WxOxH): 125x70x47 cm

Packing: 130x80x65 cm

Weight: 72 Kg

Packing weight: 102 Kg

Technical Advantages

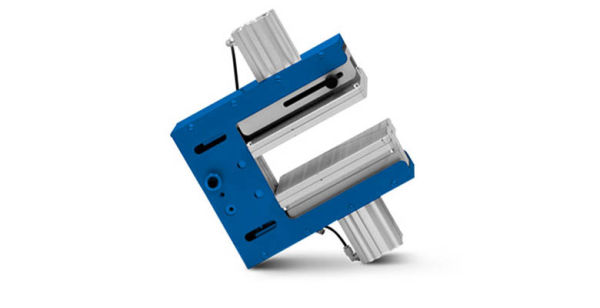

The molds also of different sizes, are automatically loaded into the clamp, the working cycle is started automatically. The operator must not press any button. Fast and simple.

The clamp center the mould. The parameters of the mould are set previously, or automatically read the RFID tags, if present in the mould. Substantial time savings.

The mould is automatically injected according to the set parameters. Easy for the operator.

The mould is rotated and automatically downloaded to the cooler, in front of the operator. Immediate and compact.

The cooler maintains constant the temperature of the moulds, cooling the waxes. You can set the temperature of the cooler directly on the touch screen.