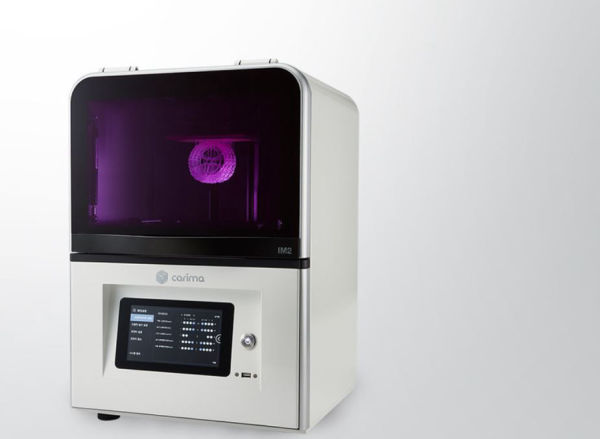

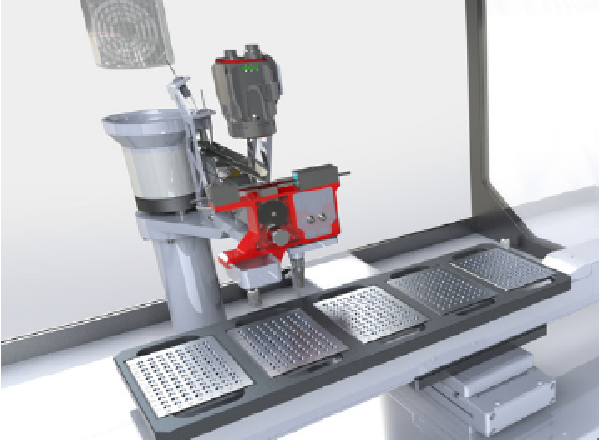

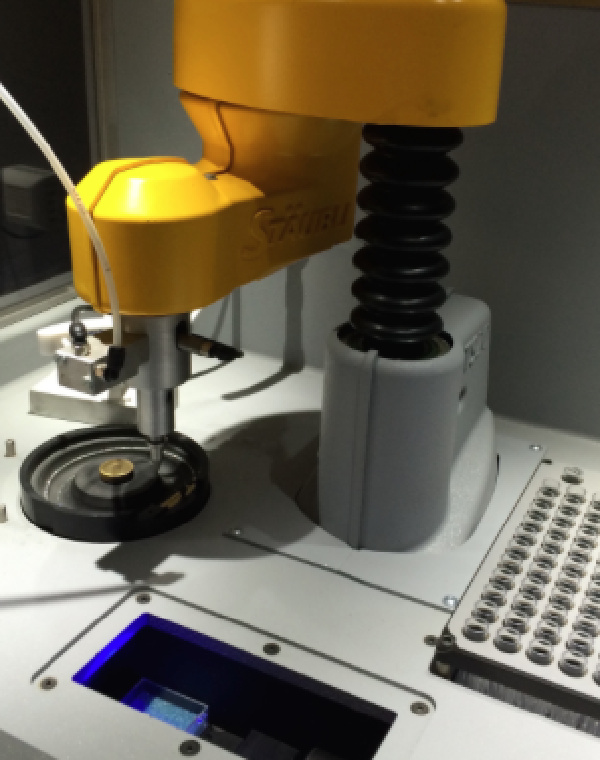

3D Printer DLP - Carima IM2

Since 1983, Carima products have been selling to dental, jewelry and model making industries in Korea, Jpaan and Germany for decades.

FAST PRINTING

With high precision and quality,

fast printing technology makes your working

environment more efficiency and professional.

(Z-Axis Max. 80mm/hour)

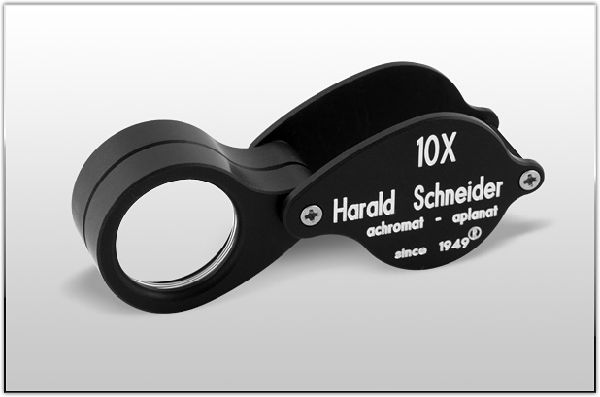

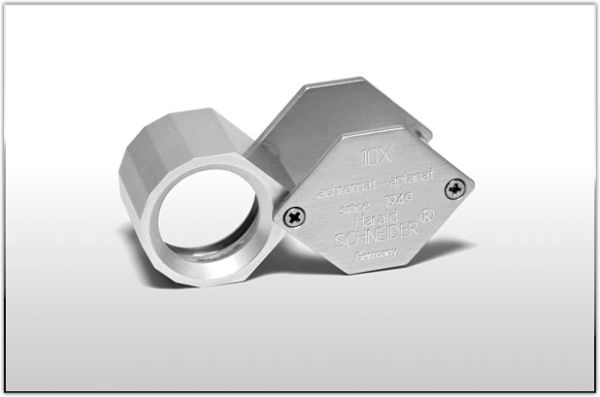

SMOOTH SURFACE

Its own advanced technology indicates how smooth surface

of printing out can be with IM2. It is necessary in Jewelry users.

HIGH PRECISION

With maximizing printing out speed,

IM2 never misses high resolution

which is 30㎛(X/Y-Axis) and 25㎛(Z-Axis) as Full High Definition.

NOISELESS ENVIRONMENT

IM2 will change your working environment

much cozy and comfortable from functioning noise.